A look behind the scenes at Dutch bed production

Long-term quality

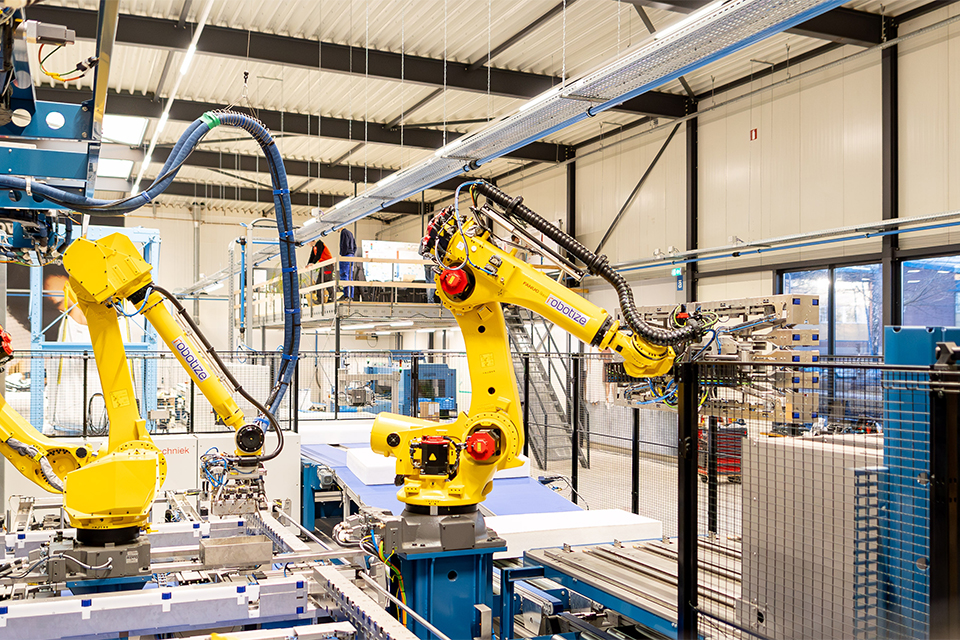

The smell of wood and metal hangs in the air. The rhythm of sewing machines can be heard in the background, further away a robotic arm lifts up a steel frame. At the factory in Deventer, people and machines work closely together on something seemingly simple: a good bed. “We make no concessions,” says Robert van Ierlant, Manager B2B at Auping. “Everything we make here has to last. That runs deep in our culture.”

Auping's story began 135 years ago with a steel spiral base for a hospital. That invention proved so durable that the principle can still be found in today's beds. Today, wood, steel and textile specialists work under one roof in Deventer. Bringing all disciplines together at the same location means shorter lines, more efficient logistics and closer cooperation between departments. This is reflected in the quality and lead times.

Production is largely automated, but in the sewing workshop (the largest in the Netherlands), craftsmanship remains visible in every detail. Here, mattresses and box springs are finished and checked by hand.

Tim Hulshorst, production manager, sees how humans and technology complement each other. “Robotisation has made our production more precise,” he says. “But humans remain indispensable. Machines provide speed, we pay attention to feel and detail.”

Made-to-measure hotel beds

For the hospitality market, Auping developed the Revive model, a modular bed with the look and feel of a luxury box spring. The furniture cover is easily replaceable, which extends the life of the bed and gives it a new look every time. This innovation is also possible with other models. For example, the frame of the Auronde can be repainted or powder-coated. Auping box springs are given a second life by reupholstering them. “Our beds are built in such a way that they can be reused with a new upholstery or finish,” Van Ierlant explains. “Hotels can therefore renew their interiors without replacing the base. That avoids waste and extends the product's lifespan.”

Caya Slinkman, soft design production manager, sees that demand for customisation increasing. “We don't sell a mass product anyway. So every bed is different. Increasingly, we are delivering real bespoke design for hospitality projects, where the customer himself provides the fabric. We test this extensively for stretch, wear resistance and fire safety before using it. The quality standard is always the same, whether it's one room or three hundred.”

In her workshop, dozens of craftsmen work on the finishing touches. The double stitching comes as standard, not as a luxury, but as a certainty. “You don't notice that right away,” says Slinkman, “It offers, an extra quality invisible to the layman, which adds years to the lifespan of a mattress.”

Circular thinking

So sustainability is not a separate project at Auping, but part of the design. Since 2018, the manufacturer has been producing the world's first fully circular mattress, made of ventilating polyester and steel. Without foam and without chemical additives, ready for the circular economy.

Auping is B Corp-certified and considered a pioneer in circular design. Yet its tone remains down-to-earth. “Sustainable production is not a marketing strategy,” says Slinkman. “It is simply the only logical way to continue.”

Designed for life

According to Van Ierlant, the slogan Designed for life sums up the company's philosophy well. “We want to make products that last and are adaptable. What you buy today should still be functional in twenty years” time.“ For the hotel industry, that mainly means security: beds that keep their shape, fabrics that have been tested for intensive use and parts that remain replaceable. ”We make no grand promises, but work from a simple conviction: quality is the only sustainable strategy."

Did you know:

- That Auping is sold in 40 countries?

- 41% of the circular Elysium mattress already consists of RPET polyesters and 100% of this mattress is recycled?

- Auping has been selling beds in the hospitality market since 2004 and has supplied more than 700 projects since then?

- Auping Essential was the world's first C2C bed?

- The box spring does not add to the quality of sleep?

-That it's better to invest in circular mattresses than wind turbines for C02 reduction?

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Royal Auping B.V..

Contact opnemen

Contact opnemen